Introduction:

A sand dredge pump works with cutter suction dredger is used to transport dredged material through a long distance pipeline, more than that, a submerged pump or ladder pump is to dredge in deep material and prevent cavitation, a booster pump either in the river or on the land is to transfer dredged material to the placement site.

Sand Production Estimation:

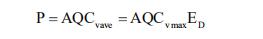

Turner (1996) presents an equation for estimating the sand production of a hydraulic cutter suction dredger, and the solid production (P) of the hydraulic cutter suction dredger is

A: a conversion factor (SI units in m³/h 0.222, Engine units of cy/hr 0.297)

Q: pump capacity (m³/h)

Ccave: average slurry concertration in volume

Cvmax: Maximum slurry cconcentration in volume

Ed: dredgeing efficiency (common dredging efficiency of two fixed spuds and spud carriage is 50% and 75% respectively)

Slurry Composition is the amount of dry solids divided by total amount of slurry with respect to volume or weight. In dredging, the concentration by volume (Cv) is

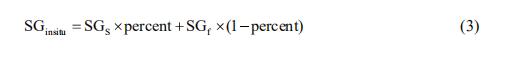

In-situ specific gravity(SGinsitu) is determined from an undisturbed sediment sample, and it is normally calculated usingthe specific gravity of the solids (SGs) andthe

concentration by volume in dredging calculations. Simply, in-situ specific gravity is

where percent meanspercentageof solid divided bythewhole sample volume. Thein-situ specific gravityis then used to calculate the in-situ production.

Theflow rate of a dredge pump isanimportant factor fordeterminingthe production. The operating flow rate is determined bythe intersection of the pump head curve

and the system head curve. However, the operating flow rate must be greater than the critical flow ratethat a fixed bed starts to move. In addition, flow ratemust be

less than the flow rate value at the intersection of the NPSHR curve and the NPSHAcurve in order to prevent cavitation.